焊接機器人維修需要注意的三點細節

來源:http://www.opedost.com/ 發布時間:2021-08-20 瀏覽次數:0

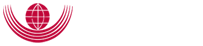

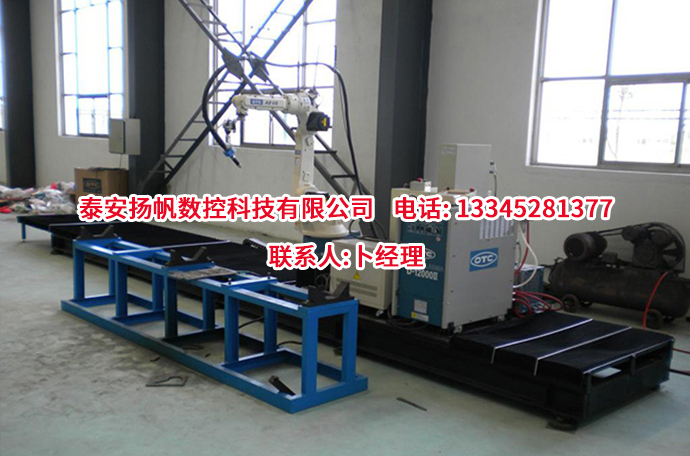

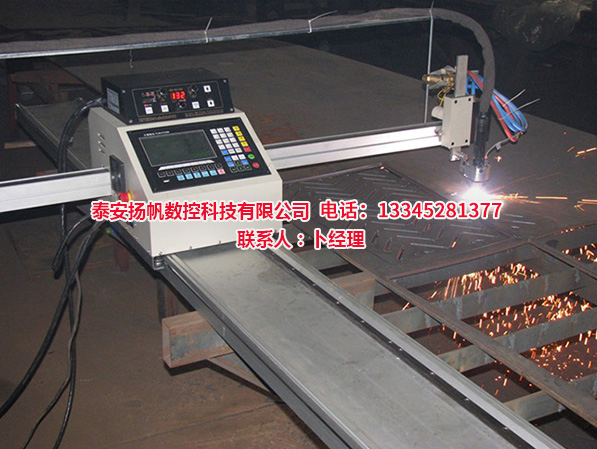

當智能化技術融入焊接設備中之后,呈現出來的是一種高科技含量的焊接機器人,由于其智能化程度比較高,所以整個焊接過程幾乎都能自動完成,大大提高 效率之外,還改善了焊接精度。即便是這樣,也不能完全做到故障率為零,當焊接機器人出現故障之后,要做的就是停機檢查,并及時將故障排除。

When the intelligent technology is integrated into the welding equipment, a high-tech welding robot is presented. Due to its high degree of intelligence, the whole welding process can be completed almost automatically, which not only greatly improves the efficiency, but also improves the welding accuracy. Even so, the failure rate cannot be completely zero. When the welding robot fails, the first thing to do is to stop the machine for inspection and eliminate the failure in time.

但考慮到焊接機器人系統的復雜性,維修的時候還是需要注意一些細節,否則有可能原有的故障沒有修好,又出現了新的問題。焊接機器人維修注意事項有如下幾點:

However, considering the complexity of the welding robot system, we still need to pay attention to some details during maintenance, otherwise the original fault may not be repaired and new problems may appear. The precautions for welding robot maintenance are as follows:

一、操作前的檢查

1、 Inspection before operation

在開始維修焊接機器人之前,先要對整個設備進行細致全 面的檢查,從而確定故障的位置和原因。主要檢查電器控制箱內是否有水、油進入;電器是否受潮;供電電壓是否符合要求;前后安 全門開關是否正常;電動機的轉方向是否一致等等。

Before starting to repair the welding robot, the whole equipment must be carefully and comprehensively inspected to determine the location and cause of the fault. Mainly check whether there is water and oil in the electrical control box; Whether the electrical appliances are damp; Whether the power supply voltage meets the requirements; Whether the front and rear safety door switches are normal; Whether the rotation direction of the motor is consistent, etc.

二、維修時的拆除

2、 Removal during maintenance

要維修機器勢必先要將其零部件拆卸下來,拆除的時候一定要記住先將電源關閉,同時還要關掉機器人的氣壓源。然后放松引拔氣缸固定板固定螺絲,并移動手臂使其靠近;移動緩沖器座,使其靠近手臂;旋緊引拔氣缸固定板,讓手臂不能移動;將旋轉安 全螺絲鎖好,使機械手不能旋轉等等,這些都是要注意的細節

To repair the machine, its parts must be removed first. When removing, remember to turn off the power first and turn off the air pressure source of the robot at the same time. Then loosen the fixing screw of the drawing cylinder fixing plate and move the arm close to it; Move the buffer seat close to the arm; Tighten the fixing plate of the drawing cylinder so that the arm cannot move; Lock the rotating safety screw so that the manipulator cannot rotate, etc. These are the details that should be paid attention to

三、完成之后的組裝

3、 Assembly after completion

當焊接機器人中的故障排除之后,還需要將剛才拆除的零件安裝上去,同樣要注意安裝的順序和位置,使設備保持完整性。

After troubleshooting in the welding robot, it is also necessary to install the parts just removed. Similarly, pay attention to the installation sequence and position to maintain the integrity of the equipment.

所以焊接機器人性能的不斷提高,人們對它的應用也越來越廣泛,在使用過程中它也勢必會遇到各種各樣的問題,大家一定要認真對待。

Therefore, with the continuous improvement of the performance of welding robot, its application is more and more widely. In the process of use, it is bound to encounter various problems, which we must take seriously.

上一篇:焊接機器人的送絲方式有哪些種?

下一篇:自動焊接機器人實施的功能要求是什么?