自動焊專機的功用特性介紹!

來源:http://www.opedost.com/ 發布時間:2021-09-17 瀏覽次數:0

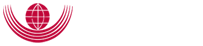

自動焊的功用特性:順應管管、管彎頭、管三通、管高頸法蘭對接;管法蘭、彎頭法蘭角接。順應碳鋼、低合金鋼、不銹鋼等多種材質的焊接可搭載氬弧焊、二保焊、MIG/MAG焊、等離子焊等多種焊接設備。

Functional characteristics of automatic welding: conform to the butt joint of pipe, pipe elbow, pipe tee and pipe high neck flange; Pipe flange, elbow flange angle joint. Comply with the welding of carbon steel, low alloy steel, stainless steel and other materials, and can be equipped with argon arc welding, secondary protection welding, MIG / MAG welding, plasma welding and other welding equipment.

自動焊機的特點:

Features of automatic welding machine:

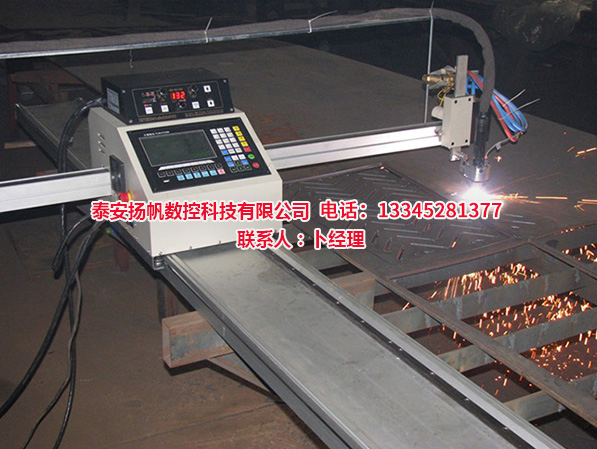

1、采用直流伺服電機,性能穩定,使用壽命長。

1. DC servo motor is adopted, with stable performance and long service life.

2、采用10寸觸摸屏做為人機交互界面,一看即懂的焊接工藝控制過程,形象直觀,簡單、易操作。

2. The 10 Inch Touch screen is used as the man-machine interface to understand the welding process control process at a glance, which is intuitive, simple and easy to operate.

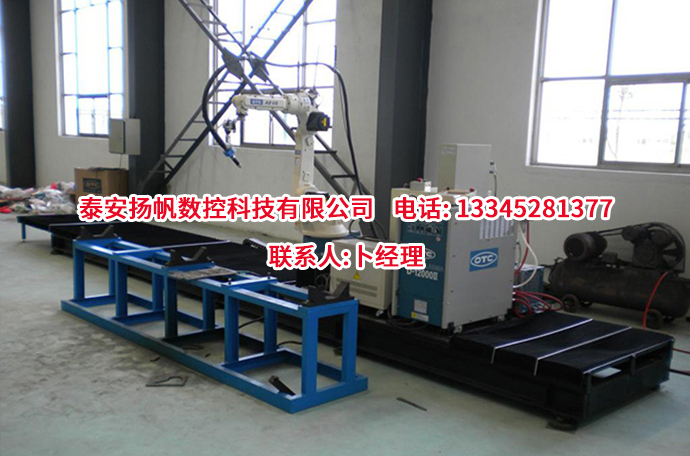

3、電弧自動跟蹤功能,也可關閉弧長控制功能,手動調節弧長。

3. The automatic arc tracking function can also turn off the arc length control function and manually adjust the arc length.

4、精密的無限回轉式旋轉結構,送絲、水、電、氣無纏繞;自帶一體式送絲機,使送絲方便可靠。

4. Precise infinite rotary structure, no winding of wire feeding, water, electricity and gas; The self-contained integrated wire feeder makes wire feeding convenient and reliable.

5、該設備可存儲60套焊接工藝參數;一個焊接工藝程序可分16個區間,以滿足工件不同時段的焊接要求。

5. The equipment can store 60 sets of welding process parameters; A welding procedure can be divided into 16 sections to meet the welding requirements of workpiece in different periods.

近二十年來,隨著數字化、自動化、計算機技術、機械設計技術的發展,以及人們對產品的質量要求的提高,焊接質量、美觀度等得到了更大的重視。特別是在08年金融危機以后,隨著我國勞動成本的增加,以及對工人的身體健康的重視和對提高生產效率的要求,。

In the past two decades, with the development of digitization, automation, computer technology and mechanical design technology, as well as the improvement of people's requirements for product quality, welding quality and aesthetics have been paid more attention. Especially after the 2008 financial crisis, with the increase of China's labor cost, the attention to the health of workers and the requirements to improve production efficiency,.

在現代工業生產中,越來越多的焊接生產過程中開始采用自動焊接專機。可以通過電氣控制,氣動控制和液壓控制技術,實現對電動機、氣動執行元件、液壓執行元件的旋轉或移動,實現工件焊縫與焊槍的相對運動,從而自動完成焊接接頭的焊接工作。

In modern industrial production, more and more automatic welding machines are used in welding production. Through electrical control, pneumatic control and hydraulic control technology, the rotation or movement of motor, pneumatic actuator and hydraulic actuator can be realized, and the relative movement of workpiece weld and welding gun can be realized, so as to automatically complete the welding of welded joints.

上一篇:焊接變形和應力產生的原因和預防

下一篇:自動焊專機的功用特性介紹!