焊接機器人使用常見的問題和解決方案

來源:http://www.opedost.com/ 發布時間:2023-01-28 瀏覽次數:0

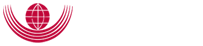

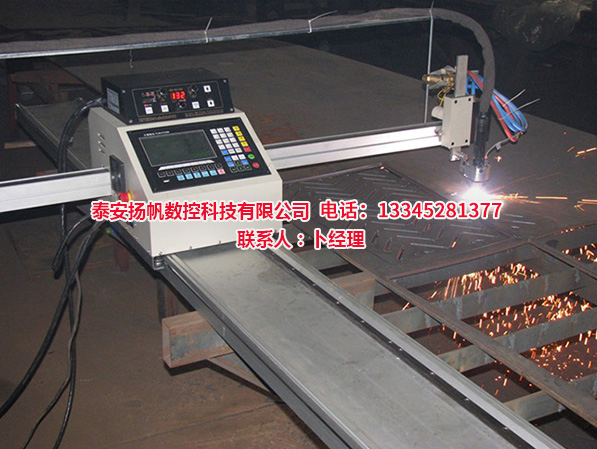

焊接機器人廣泛用于機械加工、汽車零部件、集裝箱、廚電生產等領域。焊接機器人幫助企業完成了自動化焊接作業,但是在使用中也會遇到一些問題,今天山東數控焊接設備廠家帶大家一起了解下焊接機器人使用常見的問題和解決方案。

Welding robots are widely used in mechanical processing, automobile parts, containers, kitchen appliances and other fields. Welding robots help enterprises complete automatic welding operations, but there are also some problems in use. Today, Shandong CNC welding equipment manufacturer will take you to understand the common problems and solutions in the use of welding robots.

焊縫跑偏問題:可能是焊接位置不對或找焊槍有問題。

Weld deviation problem: it may be the wrong welding position or the problem of finding the welding gun.

這時候就要考慮TCP(焊槍中心點的位置)是否準確并進行調整。如果這種情況經常發生,請檢查焊接機器人各軸的零位并重新校準糾正。

At this time, it is necessary to consider whether the TCP (position of welding torch center point) is accurate and adjust it. If this happens frequently, please check the zero position of each axis of the welding robot and recalibrate it.

沖刷問題:可能是焊接參數選擇錯誤,焊槍角度或焊槍位置錯誤,可適當調整。

Scour problem: It may be caused by incorrect selection of welding parameters, incorrect welding gun angle or welding gun position, which can be adjusted appropriately.

出現氣孔:這可能是由于氣體保護不好,工件上底漆太厚,或者保護氣體不足,可以通過適當的調整來補救。

Porosity: This may be due to poor gas protection, too thick primer on the workpiece, or insufficient protective gas, which can be remedied by proper adjustment.

飛濺過多問題:可能是由于焊接參數選擇不正確,氣體成分原因,或焊絲外伸長過長。可以調節機器功率改變焊接參數,調節氣體分配器調節氣體混合比例,調節焊槍與工件的相對位置。

Excessive spatter: It may be due to incorrect selection of welding parameters, gas composition, or excessive extension of welding wire. The machine power can be adjusted to change the welding parameters, the gas distributor can be adjusted to adjust the gas mixing ratio, and the relative position of the welding gun and the workpiece can be adjusted.

焊縫末端冷卻后形成弧坑,載編程時,可在工作步驟中添加埋弧坑功能以填充弧坑。

The crater is formed after the end of the weld is cooled. When programming, the function of submerged crater can be added in the work step to fill the crater.

在焊接過程中,機器人系統的常見故障。

Common faults of robot system during welding.

槍碰撞:可能是由于工件裝配偏差或焊槍TCP不準確,您可以檢查安裝情況或糾正焊槍TCP。

Gun collision: It may be due to workpiece assembly deviation or inaccurate welding torch TCP. You can check the installation or correct the welding torch TCP.

發生電弧故障,無法引弧-這可能是因為焊絲沒有接觸到工件或工藝參數太小。您可以手動送絲,調整焊槍與焊縫之間的距離,或相應地調整工藝參數。

An arc fault occurs and the arc cannot be started - this may be because the welding wire does not contact the workpiece or the process parameters are too small. You can manually feed the wire, adjust the distance between the welding gun and the weld, or adjust the process parameters accordingly.

保護氣監測報警:冷卻水或保護氣供應出現故障,檢查冷卻水或保護氣管道。

Protective gas monitoring alarm: if the cooling water or protective gas supply fails, check the cooling water or protective gas pipeline.

制造業的不斷發展,焊接自動化、自動化和柔性化是主要方向,目前焊接機器人作為焊接自動化的現代化標志,因其多功能性、可靠性和穩定性受到各大企業歡迎。您有需求就來我們網站http://www.opedost.com咨詢吧!

With the continuous development of the manufacturing industry, welding automation, automation and flexibility are the main directions. At present, as a modern symbol of welding automation, welding robots are welcomed by major enterprises because of their versatility, reliability and stability. Come to our website if you need http://www.opedost.com Ask!

上一篇:焊接專機重要且常用到的兩大分類

下一篇:自動焊接設備的三大分類