數控焊接設備如何能助推機械制造業?

來源:http://www.opedost.com/ 發布時間:2023-02-18 瀏覽次數:0

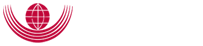

機械制造業發展中,山東數控焊接設備的應用,取代了傳統的人工焊接操作模式,能夠實現自動化、批量化以及精準化生產制造,滿足行業發展需求,推動了經濟社會發展與進步。

In the development of machinery manufacturing industry, the application of Shandong CNC welding equipment has replaced the traditional manual welding operation mode, which can realize automatic, batch and precise production and manufacturing, meet the development needs of the industry, and promote the economic and social development and progress.

1.科學智能化

1. Scientific and intelligent

數控焊接設備在機械制造中的應用,實現了自動化運行,在智能化信息技術的支撐下,具備了人機交互的特征,賦予了其智能化操作的功能,能夠實現對整個焊接工序、流程的數字化集中控制,尤其是對于較為精細的焊接部位,數字化集中控制能夠更好的保證焊接施工質量。

The application of numerical control welding equipment in mechanical manufacturing has realized automatic operation. With the support of intelligent information technology, it has the characteristics of human-computer interaction, and has given it the function of intelligent operation. It can realize the digital centralized control of the whole welding process and process, especially for the relatively fine welding parts, the digital centralized control can better ensure the welding construction quality.

在機械制造中,數控焊接設備的應用和操作具備較強的程序性,對于自動化傳感技術有著非常高的要求,進而才能夠更好的滿足機械制造及焊接工作需求。

In mechanical manufacturing, the application and operation of numerical control welding equipment is highly procedural, and has very high requirements for automatic sensing technology, which can better meet the needs of mechanical manufacturing and welding work.

2.高精準度與組合化

2. High accuracy and combination

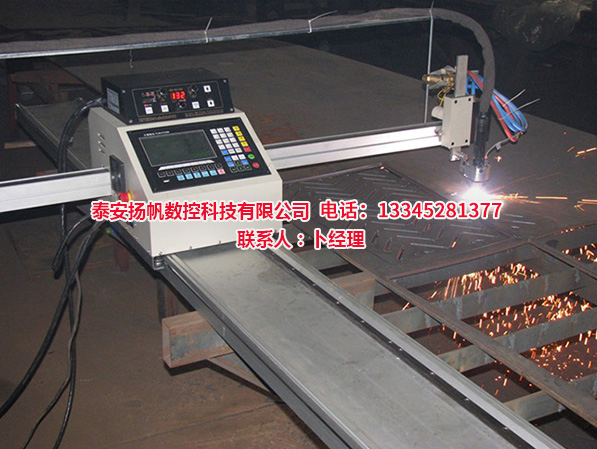

將數控焊接設備應用于機械制造業中,具備了較高的精準度及組合化特點。高精準度主要體現在利用數控系統來實現對焊接精度的精準化控制,確保焊接質量達標。一般情況下,在應用普通焊接設備時應將其焊接精度控制在1mm內,禁止超過此標準。

The application of numerical control welding equipment in the mechanical manufacturing industry has high accuracy and combination characteristics. High accuracy is mainly reflected in the use of numerical control system to achieve accurate control of welding accuracy and ensure that the welding quality reaches the standard. In general, the welding accuracy of ordinary welding equipment shall be controlled within 1mm when it is used, and it is forbidden to exceed this standard.

而應用數控焊接設備,則能夠將焊接精度控制在0.5mm內,不難看出,數控焊接設備和普通焊接設備相比較而言,具備了更高的精準度。

The application of numerical control welding equipment can control the welding accuracy within 0.5mm. It is not difficult to see that numerical control welding equipment has higher accuracy compared with ordinary welding equipment.

組合化特點主要體現在機械制造業在應用數控焊接設備的過程中,往往將設備放在大型設備上,這些設備的應用,不僅具備了綜合性特征,同時其運行效率更高,能夠為機械制造及焊接工作提供巨大的便利。

The combination characteristics are mainly reflected in the process of applying numerical control welding equipment in the machinery manufacturing industry, which often focuses on large equipment. The application of these equipment not only has comprehensive characteristics, but also has higher operating efficiency, which can provide great convenience for the machinery manufacturing and welding work.

3.監督與管理有機協調

3. Organic coordination of supervision and management

在機械制造中應用數控焊接設備,使其具備了監督和管理有機協調的特征。對于焊接設備的管理與控制,主要是利用網絡技術、計算機信息技術得以實現的。具體來說,數控焊接設備運轉期間利用局域網有效管控銜接各項焊接流程,實現對焊接工作全過程的實時化監督管理,及時的發現并遠程判斷分析解決出現的故障問題,保證焊接作業的順利、、高能效開展。

The application of numerical control welding equipment in mechanical manufacturing makes it have the characteristics of organic coordination of supervision and management. The management and control of welding equipment are mainly realized by using network technology and computer information technology. Specifically, during the operation of the NC welding equipment, the LAN is used to effectively control and link up various welding processes, realize real-time supervision and management of the whole process of welding work, timely find and remotely judge and solve the fault problems, and ensure the smooth, safe and high-efficient development of welding work.

數控焊接設備隨之出現并實現了機械制造領域中的高能效應用,將數控焊接設備應用于機械制造中,能夠更好地保障機械制造效率及質量,提升焊接工藝精度,助推機械制造業自動化發展。更多相關內容就來我們網站http://www.opedost.com咨詢吧!

CNC welding equipment has emerged and realized the high-efficient application in the field of mechanical manufacturing. Applying CNC welding equipment to mechanical manufacturing can better guarantee the efficiency and quality of mechanical manufacturing, improve the accuracy of welding process, and boost the automation development of mechanical manufacturing. Come to our website for more relevant content http://www.opedost.com Ask!

上一篇:焊接專機的運行離不開這些要點

下一篇:數控焊接設備的維修檢查步驟