對自動焊接設(shè)備進行性能檢測及質(zhì)量控制方式

來源:http://www.opedost.com/ 發(fā)布時間:2023-11-10 瀏覽次數(shù):0

檢查設(shè)備的外觀和結(jié)構(gòu),確保沒有明顯的損壞或松動的部件。

Check the appearance and structure of the equipment to ensure that there are no obvious damage or loose components.

驗證設(shè)備的電源和控制系統(tǒng),確保所有電線和電纜連接正確,電源穩(wěn)定。

Verify the power supply and control system of the equipment, ensuring that all wires and cables are connected correctly and the power supply is stable.

根據(jù)制造商提供的設(shè)備規(guī)格和操作手冊,設(shè)置焊接參數(shù),如電流、電壓、焊接速度等。

According to the equipment specifications and operation manual provided by the manufacturer, set welding parameters such as current, voltage, welding speed, etc.

校準測量儀器:確保焊接設(shè)備中的測量儀器,如電流表、電壓表等,是準確的。定期校準這些儀器。

Calibration of measuring instruments: Ensure that the measuring instruments in the welding equipment, such as ammeters, voltmeters, etc., are accurate. Regularly calibrate these instruments.

使用標準試樣:使用標準試樣(通常是相似于實際工件的樣本),進行焊接測試。這些試樣可以用于評估焊接設(shè)備的性能和質(zhì)量。

Use standard specimens: Conduct welding tests using standard specimens (usually samples similar to actual workpieces). These samples can be used to evaluate the performance and quality of welding equipment.

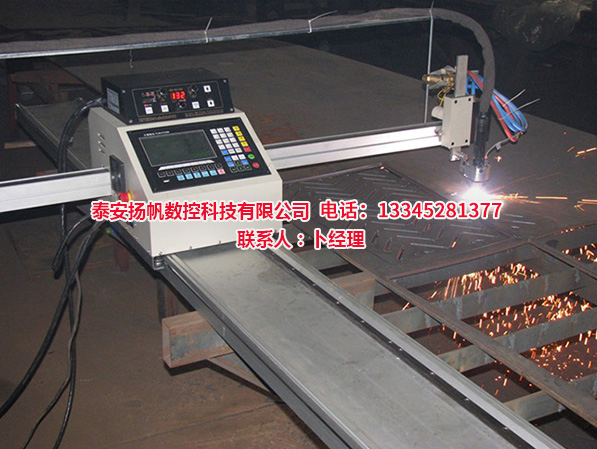

進行焊接試驗:對試樣進行焊接,以檢查焊縫的質(zhì)量和焊接參數(shù)的有效性。這可能包括檢查焊縫的強度、外觀、焊接深度等。

Conduct welding test: Weld the sample to check the quality of the weld and the effectiveness of the welding parameters. This may include checking the strength, appearance, welding depth, etc. of the weld seam.

檢查焊接參數(shù):確保焊接參數(shù)(電流、電壓、速度等)符合標準或工程要求。如果焊接參數(shù)不正確,必須進行調(diào)整。

Check welding parameters: Ensure that the welding parameters (current, voltage, speed, etc.) comply with standards or engineering requirements. If the welding parameters are incorrect, adjustments must be made.

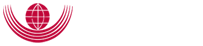

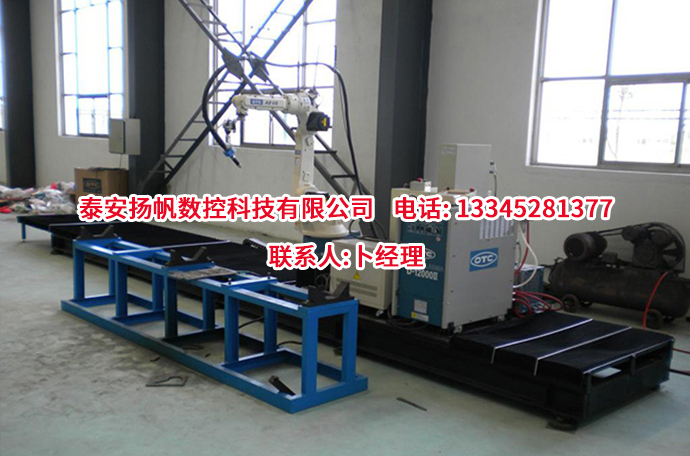

自動焊接設(shè)備

Automatic welding equipment

確保穩(wěn)定性:檢查設(shè)備的穩(wěn)定性和一致性,以確保在不同焊接任務(wù)中產(chǎn)生相似的焊接結(jié)果。

Ensure stability: Check the stability and consistency of the equipment to ensure similar welding results are produced in different welding tasks.

質(zhì)量控制記錄:維護詳細的質(zhì)量控制記錄,包括焊接參數(shù)、試驗結(jié)果、維護日志和任何問題的解決方法。

Quality control records: Maintain detailed quality control records, including welding parameters, test results, maintenance logs, and any problem-solving methods.

培訓(xùn)操作人員:確保操作人員經(jīng)過培訓(xùn),了解設(shè)備的正確使用方法,以及如何識別和處理問題。

Train operators: Ensure that operators have been trained to understand the correct use of equipment and how to identify and handle problems.

定期維護:制定定期的維護計劃,包括更換磨損部件、清潔設(shè)備、潤滑機械部件等,以確保設(shè)備的長期性能。

Regular maintenance: Develop a regular maintenance plan, including replacing worn parts, cleaning equipment, lubricating mechanical components, etc., to ensure the long-term performance of the equipment.

遵守規(guī)定:遵循焊接規(guī)定,包括焊接區(qū)域的通風(fēng)、防護裝備、火災(zāi)等。

Comply with safety regulations: Comply with welding safety regulations, including ventilation, protective equipment, fire safety, etc. in the welding area.

標記和追溯:為每個焊接任務(wù)標記焊接時間、操作人員、焊材批次等信息,以便追溯和質(zhì)量控制。

Marking and traceability: Mark welding time, operators, welding material batches, and other information for each welding task for traceability and quality control.

不斷改進:根據(jù)性能測試和質(zhì)量控制結(jié)果,進行持續(xù)改進,以提高焊接設(shè)備的性能和質(zhì)量。

Continuous improvement: Based on performance testing and quality control results, continuous improvement is carried out to improve the performance and quality of welding equipment.

性能檢測和質(zhì)量控制對于確保自動焊接設(shè)備的可靠性和焊接質(zhì)量關(guān)重要。通過定期的檢測和記錄,可以確保設(shè)備在整個生產(chǎn)過程中保持穩(wěn)定的性能。

Performance testing and quality control are crucial for ensuring the reliability and welding quality of automatic welding equipment. Through regular testing and recording, it can be ensured that the equipment maintains stable performance throughout the entire production process.

本文由山東焊接專機為您提供,我們的網(wǎng)站是:http://www.opedost.com將以全心全意的熱情為您提供服務(wù),歡迎您的訪問!

This article is provided by Shandong Welding Machine, and our website is: http://www.opedost.com We will provide you with wholehearted enthusiasm and welcome your visit!