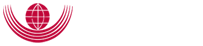

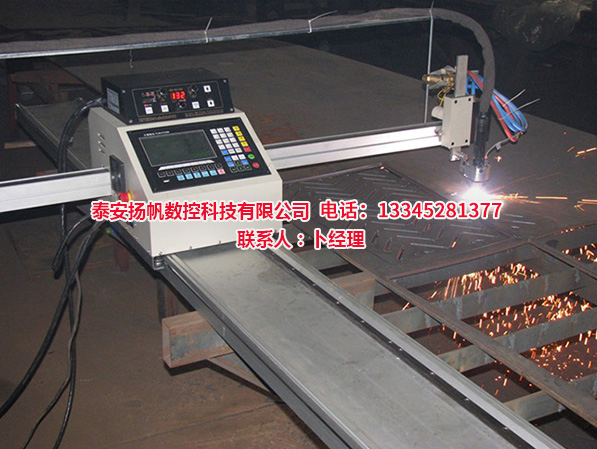

數控焊接過程

來源:http://www.opedost.com/ 發布時間:2024-11-12 瀏覽次數:0

1、熔焊

1、熔焊

1. Fusion welding

熔焊是在焊接過程中將工件接口加熱熔化狀態,不加壓力完成焊接的方法。熔焊時,熱源將待焊兩工件接口處迅速加熱熔化,形成熔池。熔池隨熱源向前移動,冷卻后形成連續焊縫而將兩工件連接成為一體。

Fusion welding is a method of heating the workpiece interface to a molten state during the welding process, without applying pressure to complete the welding. During fusion welding, the heat source rapidly heats and melts the interface between the two workpieces to be welded, forming a molten pool. The molten pool moves forward with the heat source and forms a continuous weld after cooling, connecting the two workpieces into one.

2、壓焊

2. Pressure welding

壓焊是在加壓條件下,使兩工件在固態下實現原子間結合,又稱固態焊接。常用的壓焊工藝是電阻對焊,當電流通過兩工件的連接端時,該處因電阻很大而溫度上升,當加熱塑性狀態時,在軸向壓力作用下連接成為一體。

Pressure welding is the process of achieving atomic bonding between two workpieces in a solid state under pressure, also known as solid-state welding. The commonly used pressure welding process is resistance welding. When current passes through the connection end of two workpieces, the temperature rises due to the high resistance. When heated to a plastic state, the connection becomes integrated under axial pressure.

3、釬焊

3. Brazing

釬焊是使用比工件熔點低的金屬材料作釬料,將工件和釬料加熱到高于釬料熔點、低于工件熔點的溫度,利用液態釬料潤濕工件,填充接口間隙并與工件實現原子間的相互擴散,從而實現焊接的方法。

Brazing is a welding method that uses a metal material with a lower melting point than the workpiece as the brazing material. The workpiece and brazing material are heated to a temperature higher than the melting point of the brazing material but lower than the melting point of the workpiece. The liquid brazing material is used to wet the workpiece, fill the interface gap, and achieve atomic diffusion with the workpiece, thereby achieving welding.

焊接工藝和焊接方法等因素有關,操作時需根據被焊工件的材質、牌號、化學成分,焊件結構類型,焊接性能要求來確定。

The welding process and welding method are related factors, and the operation should be determined based on the material, grade, chemical composition, welding structure type, and welding performance requirements of the welded workpiece.

本文由 山東數控焊接設備 提供幫助,更多的相關內容請點擊:http://www.opedost.com 希望本文能夠為您帶來幫助,感謝您的閱讀!

This article is assisted by Shandong CNC welding equipment. For more related content, please click: http://www.opedost.com I hope this article can be helpful to you. Thank you for reading!