數(shù)控焊接技術(shù):未來(lái)發(fā)展趨勢(shì)與創(chuàng)新

來(lái)源:http://www.opedost.com/ 發(fā)布時(shí)間:2024-12-05 瀏覽次數(shù):0

摘要:

Summary:

數(shù)控焊接技術(shù)正處在快速發(fā)展的階段,新技術(shù)和創(chuàng)新不斷涌現(xiàn)。本文將探討數(shù)控焊接技術(shù)的未來(lái)發(fā)展趨勢(shì)和潛在的創(chuàng)新點(diǎn)。

Numerical control welding technology is in a stage of rapid development, with new technologies and innovations constantly emerging. This article will explore the future development trends and potential innovation points of CNC welding technology.

正文:

Main text:

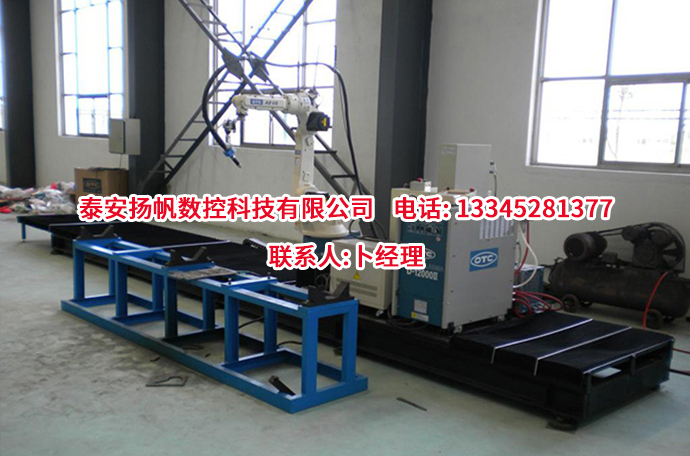

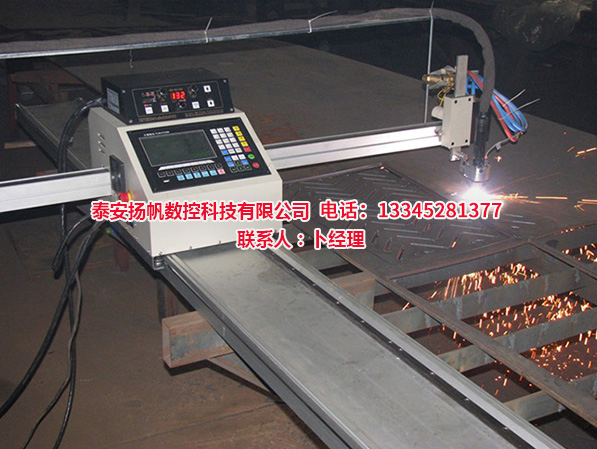

數(shù)控焊接技術(shù)的未來(lái)發(fā)展趨勢(shì)主要集中在提高自動(dòng)化程度、智能化和環(huán)境適應(yīng)性上。

The future development trend of CNC welding technology mainly focuses on improving automation, intelligence, and environmental adaptability.

自動(dòng)化程度提升:隨著機(jī)器人技術(shù)的發(fā)展,未來(lái)的數(shù)控焊接設(shè)備將更加自動(dòng)化,能夠完成更復(fù)雜的焊接任務(wù)。

Improved automation level: With the development of robot technology, future CNC welding equipment will become more automated and capable of completing more complex welding tasks.

智能化發(fā)展:通過(guò)集成的傳感器和人工智能技術(shù),數(shù)控焊接設(shè)備將能夠自我學(xué)習(xí)和適應(yīng)不同的焊接環(huán)境,自動(dòng)優(yōu)化焊接參數(shù)。

Intelligent development: By integrating advanced sensors and artificial intelligence technology, CNC welding equipment will be able to self learn and adapt to different welding environments, automatically optimizing welding parameters.

環(huán)境適應(yīng)性:未來(lái)的數(shù)控焊接設(shè)備將更加靈活,能夠適應(yīng)不同的工作環(huán)境和材料,包括極端溫度和壓力條件。

Environmental adaptability: Future CNC welding equipment will be more flexible and able to adapt to different working environments and materials, including extreme temperature and pressure conditions.

能源效率:隨著對(duì)能源效率的日益關(guān)注,未來(lái)的數(shù)控焊接設(shè)備將更加,減少能源消耗和環(huán)境影響。

Energy efficiency: With increasing attention to energy efficiency, future CNC welding equipment will be more energy-efficient, reducing energy consumption and environmental impact.

創(chuàng)新點(diǎn):

Innovation point:

無(wú)線控制:無(wú)線控制技術(shù)的應(yīng)用將使數(shù)控焊接設(shè)備的操作更加靈活和便捷。

Wireless control: The application of wireless control technology will make the operation of CNC welding equipment more flexible and convenient.

打印與焊接結(jié)合:3D打印技術(shù)與數(shù)控焊接的結(jié)合將為復(fù)雜結(jié)構(gòu)的制造提供新的可能性。

The combination of printing and welding: The integration of 3D printing technology and CNC welding will provide new possibilities for the manufacturing of complex structures.

虛擬現(xiàn)實(shí)培訓(xùn):虛擬現(xiàn)實(shí)技術(shù)的應(yīng)用將為數(shù)控焊接操作員提供更有效的培訓(xùn)手段。

Virtual reality training: The application of virtual reality technology will provide more effective training methods for CNC welding operators.

結(jié)語(yǔ):

Conclusion:

數(shù)控焊接技術(shù)的未來(lái)充滿(mǎn)挑戰(zhàn)和機(jī)遇,新技術(shù)和創(chuàng)新將推動(dòng)這一領(lǐng)域的發(fā)展,為制造業(yè)帶來(lái)更多的可能性。

The future of CNC welding technology is full of challenges and opportunities, and new technologies and innovations will drive the development of this field, bringing more possibilities to the manufacturing industry.

本文由山東數(shù)控焊接設(shè)備為您提供,我們的網(wǎng)站http://www.opedost.com我們將以全心全意的熱情為您提供服務(wù),歡迎您的訪問(wèn)

This article is provided by Shandong CNC Welding Equipment on our website http://www.opedost.com We will provide you with wholehearted enthusiasm and welcome your visit

上一篇:山東數(shù)控焊接設(shè)備:鑄件開(kāi)裂原因有哪些?

下一篇:焊接專(zhuān)機(jī)的技術(shù)特點(diǎn)與應(yīng)用領(lǐng)域