自動焊機焊接中常出的問題你知道多少?

來源:http://www.opedost.com/ 發布時間:2024-06-17 瀏覽次數:0

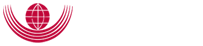

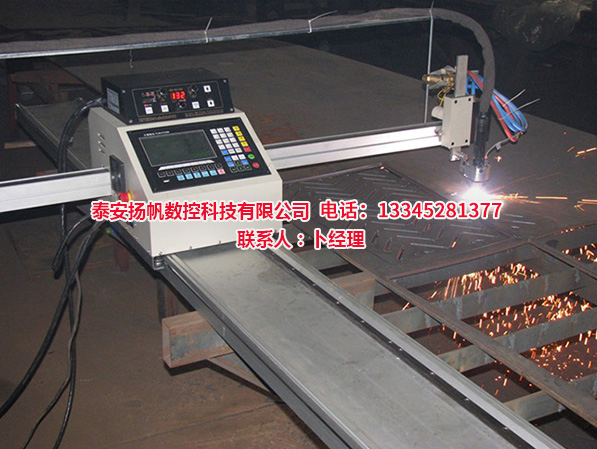

在自動焊機焊接過程中,常見的問題主要包括電源和氣源問題、電弧不穩定、過熱、電路板故障、撞槍、電弧故障、保護氣監控報警等。這些問題可能由多種原因引起,包括但不限于電源線路不良、電源不穩定、氣源或液壓源未打開、電極磨損、電纜連接松動、連續焊接時間過長、環境溫度過高、冷卻水或保護氣供給故障等。

In the welding process of automatic welding machines, common problems mainly include power and gas supply issues, unstable arc, overheating, circuit board failures, gun collision, arc faults, protective gas monitoring alarms, etc. These problems may be caused by various reasons, including but not limited to poor power lines, unstable power supply, failure to open air or hydraulic sources, electrode wear, loose cable connections, prolonged continuous welding time, high ambient temperature, cooling water or protective gas supply failure, etc.

解決這些問題的方法包括日常檢查開關電源、氣源、液壓源是否正常工作,定期檢查電極狀態,保持電源穩定,確保所有連接牢固,注意控制焊接時間,避免在高溫環境下使用焊機,及時維護并保持干燥通風的工作環境等。此外,對于焊接機器人,常見故障還包括環縫焊接成型粗細不一、管頭燒穿、顏色不好、有氣孔夾渣等,這些問題與焊接工藝、焊接狀態準備工作、作業人員熟練度等有密切關系。

The methods to solve these problems include daily inspection of the switch power supply, air source, and hydraulic source for normal operation, regular inspection of electrode status, maintaining stable power supply, ensuring all connections are firm, paying attention to controlling welding time, avoiding the use of welding machines in high-temperature environments, and timely maintenance and maintaining a dry and ventilated working environment. In addition, for welding robots, common faults include uneven thickness of circumferential welding, burning through of pipe heads, poor color, porosity and slag inclusion, etc. These problems are closely related to welding process, preparation of welding status, and proficiency of operators.

因此,提高零件制備質量和焊件裝配精度,編制專用的焊接工藝,對零件尺寸、焊縫坡口、裝配尺寸進行嚴格的工藝規定,采用精度較高的裝配工裝以提高焊件的裝配精度等措施是預防和解決這些問題的有效方法

Therefore, improving the preparation quality of parts and the assembly accuracy of welded parts, developing specialized welding processes, strictly regulating the process of part size, weld groove, and assembly size, and adopting high-precision assembly fixtures to improve the assembly accuracy of welded parts are effective methods to prevent and solve these problems

本文由 山東數控焊接設備 為您精心提供,如想了解更多請點擊我們的網站:http://www.opedost.com,我們將會以的熱情為您解答!

This article is carefully provided by Shandong CNC welding equipment. If you want to learn more, please click on our website: http://www.opedost.com We will answer you with enthusiasm!

上一篇:自動焊接設備在全位置焊中的應用

下一篇:自動焊接設備的類型及組成