自動焊接專機(jī)在現(xiàn)代工業(yè)中的應(yīng)用與挑戰(zhàn)

來源:http://www.opedost.com/ 發(fā)布時間:2024-12-09 瀏覽次數(shù):0

隨著數(shù)字化和自動化技術(shù)的快速發(fā)展,自動焊接專機(jī)在現(xiàn)代工業(yè)生產(chǎn)中得到了廣泛應(yīng)用。自動焊接專機(jī)是一種專門設(shè)計用于特定工件和焊接接頭的自動化設(shè)備,通過電氣、氣動和液壓控制技術(shù)實現(xiàn)焊接過程的自動化。這種設(shè)備不僅提高了生產(chǎn)效率,還顯著提升了焊接質(zhì)量和一致性,尤其在汽車、建筑和重工業(yè)等領(lǐng)域表現(xiàn)突出。

With the rapid development of digitalization and automation technology, automatic welding machines have been widely used in modern industrial production. Automatic welding machine is an automated equipment specifically designed for specific workpieces and welding joints, which achieves automation of the welding process through electrical, pneumatic, and hydraulic control technologies. This equipment not only improves production efficiency, but also significantly enhances welding quality and consistency, especially in fields such as automotive, construction, and heavy industry.

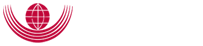

自動焊接專機(jī)通常由焊接系統(tǒng)、機(jī)械系統(tǒng)和電氣控制系統(tǒng)組成。焊接系統(tǒng)包括焊接電源和焊槍,機(jī)械系統(tǒng)負(fù)責(zé)工件的固定、定位和移動,而電氣控制系統(tǒng)則控制夾具裝夾、焊機(jī)啟動、焊槍或工件運(yùn)動等。根據(jù)控制方式的不同,自動焊接專機(jī)可分為開環(huán)控制型、閉環(huán)控制型和智能化控制型。其中,開環(huán)控制型結(jié)構(gòu)簡單、成本較低,但無法對焊接參數(shù)進(jìn)行閉環(huán)反饋控制;閉環(huán)控制型配備傳感器和電子檢測線路,適用于高精度要求的焊接任務(wù);智能化控制型則利用傳感元件和計算機(jī)軟件系統(tǒng),實現(xiàn)自動編程和焊接參數(shù)調(diào)用,但成本較高。

Automatic welding machines are usually composed of welding systems, mechanical systems, and electrical control systems. The welding system includes a welding power source and a welding gun. The mechanical system is responsible for fixing, positioning, and moving the workpiece, while the electrical control system controls fixture clamping, welding machine start-up, welding gun or workpiece movement, etc. According to different control methods, automatic welding machines can be divided into open-loop control type, closed-loop control type, and intelligent control type. Among them, the open-loop control type has a simple structure and low cost, but cannot perform closed-loop feedback control on welding parameters; The closed-loop control type is equipped with sensors and electronic detection circuits, suitable for high-precision welding tasks; The intelligent control type utilizes advanced sensing components and computer software systems to achieve automatic programming and welding parameter calling, but the cost is relatively high.

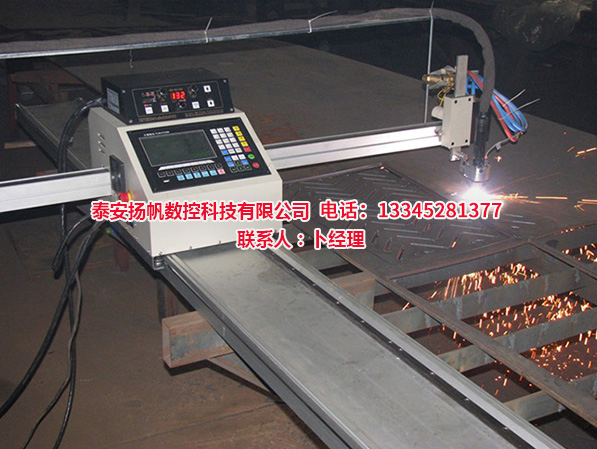

在實際應(yīng)用中,自動焊接專機(jī)廣泛應(yīng)用于工程機(jī)械行業(yè)。例如,針對起重機(jī)吊臂蓋板對接焊縫、壓路機(jī)滾筒焊縫等關(guān)鍵焊縫,焊接專機(jī)能夠大大提高焊縫質(zhì)量的穩(wěn)定性,減輕工人的勞動強(qiáng)度。此外,自動化焊接專機(jī)還被用于大型薄板結(jié)構(gòu)件的焊接,如集裝箱下波紋板的焊接,通過激光視覺傳感器實時監(jiān)測焊縫軌跡,并自動調(diào)整焊接位置和參數(shù),從而實現(xiàn)高質(zhì)量的無人化焊接。

In practical applications, automatic welding machines are widely used in the construction machinery industry. For example, welding machines can greatly improve the stability of weld quality and reduce the labor intensity of workers for key welds such as the butt weld of crane boom cover plates and roller drum welds. In addition, automated welding machines are also used for welding large thin plate structural components, such as welding corrugated plates under containers. Laser vision sensors monitor the weld trajectory in real time and automatically adjust the welding position and parameters, thereby achieving high-quality unmanned welding.

然而,自動焊接專機(jī)也面臨一些挑戰(zhàn)。由于其柔性較差,通常適用于規(guī)則焊縫的生產(chǎn),難以應(yīng)對復(fù)雜多變的焊接任務(wù)。因此,在一些需要頻繁更換焊接任務(wù)或在危險環(huán)境中進(jìn)行焊接的場景中,焊接機(jī)器人可能更為適用。未來,隨著技術(shù)的進(jìn)步,自動焊接專機(jī)的功能將進(jìn)一步提升,智能化程度也將不斷提高,為制造業(yè)帶來更多的便利和效益。

However, automatic welding machines also face some challenges. Due to its poor flexibility, it is usually suitable for the production of regular welds and difficult to cope with complex and changing welding tasks. Therefore, in some scenarios that require frequent replacement of welding tasks or welding in hazardous environments, welding robots may be more suitable. In the future, with the advancement of technology, the functions of automatic welding machines will be further improved, and the level of intelligence will continue to increase, bringing more convenience and benefits to the manufacturing industry.

本文由山東焊接專機(jī)為您提供,我們的網(wǎng)站http://www.opedost.com我們將以全心全意的熱情為您提供服務(wù),歡迎您的訪問

This article is provided by Shandong Welding Special Machine for you on our website http://www.opedost.com We will provide you with wholehearted enthusiasm and welcome your visit

上一篇:數(shù)控焊接技術(shù):現(xiàn)代工業(yè)的焊接革命

下一篇:接專機(jī)與焊接機(jī)器人的對比及其發(fā)展趨勢