接專機與焊接機器人的對比及其發展趨勢

來源:http://www.opedost.com/ 發布時間:2024-12-12 瀏覽次數:0

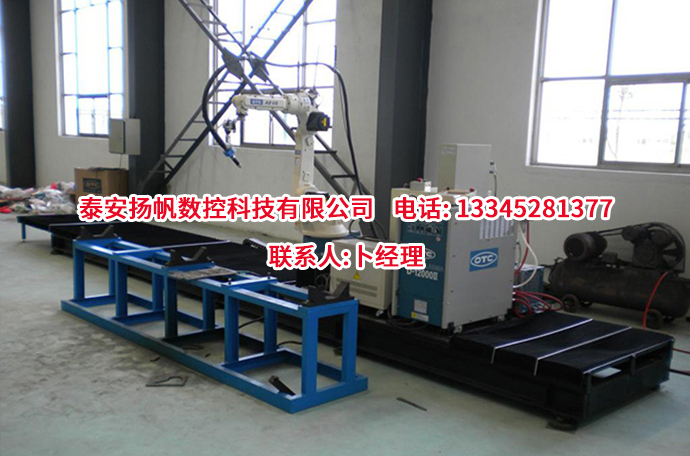

在現代制造業中,焊接專機和焊接機器人是兩種常見的自動化設備,它們各有優缺點,適用于不同的應用場景。焊接專機以其成本低廉、操作簡單的特點,在大批量生產中得到了廣泛應用。例如,針對長直焊縫或圓環焊縫的生產,焊接專機能夠完成任務,并且相對較低。

In modern manufacturing, welding machines and welding robots are two common types of automation equipment, each with its own advantages and disadvantages, suitable for different application scenarios. Welding machines have been widely used in mass production due to their low cost and simple operation. For example, for the production of long straight welds or circular welds, welding machines can efficiently complete tasks and have relatively low prices.

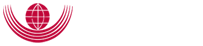

相比之下,焊接機器人具有更高的靈活性和適應性,能夠執行多種焊接任務,并在危險環境中進行操作。然而,焊接機器人的成本較高,且需要復雜的編程和維護。此外,焊接機器人在處理復雜形狀或不規則焊縫時表現出色,但在大批量生產中可能不如焊接專機。

In contrast, welding robots have higher flexibility and adaptability, can perform various welding tasks, and operate in hazardous environments. However, welding robots have high costs and require complex programming and maintenance. In addition, welding robots perform well in handling complex shapes or irregular welds, but may not be as efficient as welding machines in mass production.

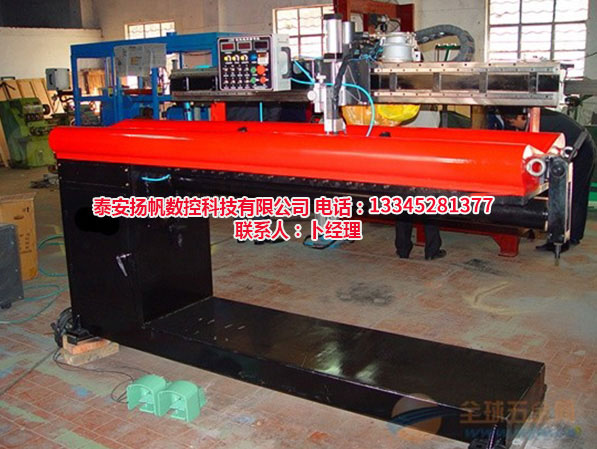

從發展趨勢來看,隨著工業4.0的推進,智能化和數字化技術的應用將成為焊接專機發展的關鍵方向。例如,基于PLC的智能焊接專機系統已經在實際生產中得到應用,通過自動化控制技術和傳感器技術的結合,顯著提高了焊接質量和生產效率。此外,激光焊縫跟蹤技術的應用也使得焊接專機能夠更好地適應復雜工件的焊接需求。

From the perspective of development trends, with the advancement of Industry 4.0, the application of intelligent and digital technologies will become a key direction for the development of welding special machines. For example, the intelligent welding machine system based on PLC has been applied in practical production, significantly improving welding quality and production efficiency through the combination of automation control technology and sensor technology. In addition, the application of laser weld seam tracking technology also enables welding machines to better adapt to the welding needs of complex workpieces.

未來,焊接專機將朝著大型化、組合化、數字化和智能化的方向發展。一方面,通過提升制造精度和控制軟件功能,實現一人多機作業;另一方面,結合機器人技術,開發出更加靈活的焊接解決方案。這些技術進步不僅將推動焊接專機在工程機械、汽車制造等領域的廣泛應用,還將為制造業的整體升級提供強有力的技術支持。

In the future, welding machines will develop towards large-scale, modular, digital, and intelligent directions. On the one hand, by improving manufacturing accuracy and controlling software functions, it is possible to achieve multi machine operation by one person; On the other hand, by combining robot technology, more flexible and efficient welding solutions have been developed. These technological advancements will not only promote the widespread application of welding machines in fields such as engineering machinery and automotive manufacturing, but also provide strong technical support for the overall upgrading of the manufacturing industry.

本文由山東焊接專機為您提供,我們的網站http://www.opedost.com我們將以全心全意的熱情為您提供服務,歡迎您的訪問

This article is provided by Shandong Welding Special Machine for you on our website http://www.opedost.com We will provide you with wholehearted enthusiasm and welcome your visit

上一篇:自動焊接專機在現代工業中的應用與挑戰

下一篇:數控焊接設備怎么操作