濟南自動焊接機:焊接三要素

來源:http://www.opedost.com/ 發(fā)布時間:2024-07-06 瀏覽次數(shù):0

1、焊接間隙

1. Welding gap

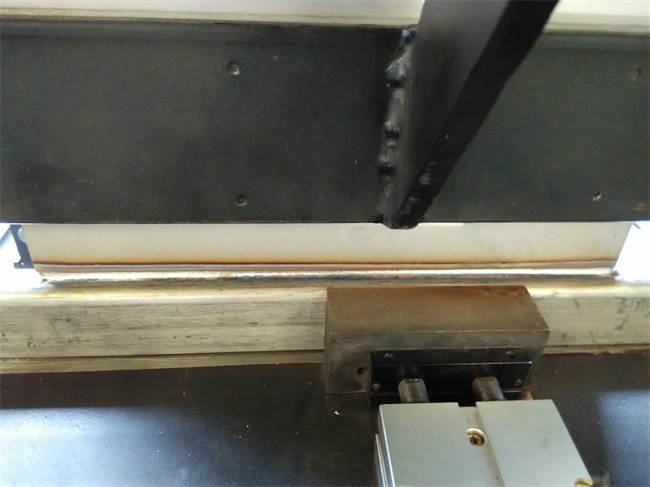

焊接間隙也稱為對應(yīng)間隙,即焊接部件之間的間隙。焊接間隙直接關(guān)系到焊接質(zhì)量。

Welding gap, also known as corresponding gap, refers to the gap between welded components. The welding gap is directly related to the welding quality.

當(dāng)焊接間隙過小時,焊縫不易穿透;當(dāng)焊接間隙過大時,會增加焊接難度,填充量過大會影響焊接進度,增加焊接應(yīng)力,容易產(chǎn)生焊接變形。

When the welding gap is too small, the weld seam is not easy to penetrate; When the welding gap is too large, it will increase the difficulty of welding. Excessive filling will affect the welding progress, increase welding stress, and easily cause welding deformation.

2、鈍邊尺寸

2. Blunt edge size

鈍邊尺寸也稱為坡口尺寸。對于U形槽,它還包括弧形r的尺寸

Blunt edge size is also known as groove size. For the U-shaped groove, it also includes the size of the arc-shaped r

過大或過小的鈍邊會影響焊接質(zhì)量,過小的鈍邊易引起燒穿,過大的鈍邊易引起未焊透。如果接頭兩側(cè)的鈍邊同時太大或太小,則通過調(diào)節(jié)電流來控制穿透更容易處理。

Blunt edges that are too large or too small can affect welding quality. Blunt edges that are too small can cause burn through, while blunt edges that are too large can cause incomplete penetration. If the blunt edges on both sides of the joint are too large or too small at the same time, it is easier to control penetration by adjusting the current.

如果一邊是大的,另一邊是小的,如果選擇小電流,它將不會焊接通過。如果使用高電流,它會燒穿。因此,這種情況應(yīng)引起足夠的重視,特別是在單面焊和雙面成形的焊接工作中。

If one side is large and the other side is small, if low current is chosen, it will not solder through. If high current is used, it will burn through. Therefore, this situation should be given sufficient attention, especially in single-sided welding and double-sided forming welding work.

u形坡口是一種節(jié)省焊接材料的坡口形式,但電弧R的大小必須保證焊條或焊絲能容易地到達坡口底部進行焊接。

U-shaped groove is a groove form that saves welding materials, but the size of the arc R must ensure that the welding rod or wire can easily reach the bottom of the groove for welding.

3、坡口角度

3. Slope angle

坡口角度過大或過小都會不同程度地影響焊接質(zhì)量。表面上,過大的坡口角度只會導(dǎo)致更多的填充金屬和更長的焊接時間,從而影響經(jīng)濟效益。然而,焊接后,另一個令人頭痛的問題將出現(xiàn):焊接變形增加。這些問題應(yīng)該盡可能避免。

Excessive or insufficient bevel angle can affect welding quality to varying degrees. On the surface, an excessively large groove angle will only lead to more filler metal and longer welding time, thereby affecting economic benefits. However, after welding, another headache inducing issue will arise: increased welding deformation. These issues should be avoided as much as possible.

如果出現(xiàn)這種問題,可以找到以下解決辦法:如果板的尺寸足夠大,凹槽可以重新切割到正確的尺寸;組裝接頭前,進行堆焊,使坡口尺寸正確;

If this problem occurs, the following solutions can be found: if the size of the board is large enough, the grooves can be re cut to the correct size; Before assembling the joint, perform overlay welding to ensure that the groove size is correct;

坡口角太小。由于坡口口角過小而產(chǎn)生的直接的問題是熔深不足,容易夾渣。另外熔深不足在某些情況下會影響焊縫有效厚度的大小,從而降低焊縫強度,所以必須引起重視。

The bevel angle is too small. The most direct problem caused by a small groove angle is insufficient penetration, which can easily lead to slag inclusion. In addition, insufficient penetration can in some cases affect the effective thickness of the weld, thereby reducing the strength of the weld, so it must be taken seriously.

另一個隱藏的問題是傾斜角太小,容易產(chǎn)生裂縫,應(yīng)該避免。針對坡口口角過小的問題,有將坡口再次切割或磨削成正確的尺寸的解決方法。改變組裝時適當(dāng)增大坡口根部的間隙的根焊道的焊接方法。

Another hidden issue is that the tilt angle is too small, which can easily cause cracks and should be avoided. There is a solution to the problem of small bevel angles by re cutting or grinding the bevel to the correct size. Change the welding method of the root weld bead by appropriately increasing the gap at the root of the groove during assembly.