激光焊接的特點有哪些?

來源:http://www.opedost.com/ 發布時間:2024-11-07 瀏覽次數:0

1、高功率密度與小熱影響區

1. High power density and small heat affected zone

激光焊接中的激光功率密度可達10^510^7 W/cm?。由于激光束的聚焦效果,材料的熱影響區非常窄,產生的變形也小。這使得激光焊接特別適合于焊接和微細焊接,能夠實現高質量的焊接接頭。

The laser power density in laser welding can reach 10 ^ 5 to 10 ^ 7 W/cm?. Due to the focusing effect of the laser beam, the heat affected zone of the material is very narrow, and the deformation generated is also small. This makes laser welding particularly suitable for welding and micro welding, enabling high-quality welded joints.

2、厚件焊接與不開坡口焊接

2. Thick piece welding and non beveled welding

激光焊接可以在不需要坡口的情況下直接焊接厚件,能夠獲得深寬比大的焊縫。例如,單道焊接鋼板的厚度已可以達到50mm。這種特性簡化了焊接過程并提升了效率。

Laser welding can directly weld thick parts without the need for grooves, and can obtain welds with a large aspect ratio. For example, the thickness of a single welded steel plate can reach 50mm. This feature simplifies the welding process and improves efficiency.

3、難焊材料的焊接能力

3. Welding ability of difficult to weld materials

激光焊接適用于傳統焊接方法難以處理的材料,包括難熔金屬、熱敏感性強的金屬,以及熱物理性能差異懸殊的材料。此外,激光焊接也能用于非金屬材料,如陶瓷和有機玻璃等。

Laser welding is suitable for materials that are difficult to process using traditional welding methods, including refractory metals, metals with strong thermal sensitivity, and materials with vastly different thermal and physical properties. In addition, laser welding can also be used for non-metallic materials such as ceramics and organic glass.

4、密閉容器內焊接

4. Welding inside a sealed container

激光束可以穿過透明介質焊接密閉容器內的工件,適用于在玻璃封閉容器中焊接如鈹合金等劇毒材料。這一特性增強了激光焊接在特種環境中的應用能力。

The laser beam can pass through transparent media to weld workpieces inside sealed containers, and is suitable for welding highly toxic materials such as beryllium alloy in glass sealed containers. This feature enhances the application capability of laser welding in special environments.

5、光束傳輸與反射

5. Beam transmission and reflection

激光焊接通過反射鏡可以將激光束送達傳統焊接方法無法到達的部位。YAG激光器(波長1.06μm)還可以通過光纖進行傳輸,進一步提高了激光焊接的可達性。

Laser welding can deliver laser beams to areas that traditional welding methods cannot reach through mirrors. YAG laser (wavelength 1.06 μ m) can also be transmitted through optical fibers, further improving the accessibility of laser welding.

6、免電磁干擾

6. Free from electromagnetic interference

激光束不受電磁干擾,沒有磁偏吹現象,這使得激光焊接特別適合用于磁性材料的焊接。

The laser beam is not affected by electromagnetic interference and there is no magnetic bias blowing phenomenon, which makes laser welding particularly suitable for welding magnetic materials.

7、操作簡便與性

7. Easy to operate and safe

激光焊接無需真空室,不產生X射線,因此觀察和對中過程更加便捷、。

Laser welding does not require a vacuum chamber and does not produce X-rays, making the observation and alignment process more convenient and safe.

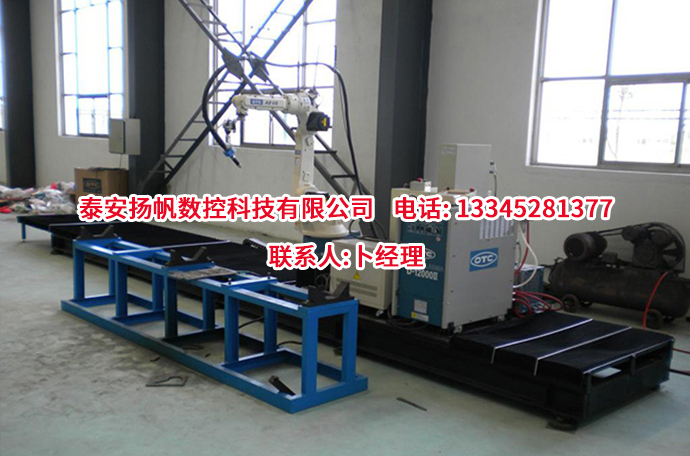

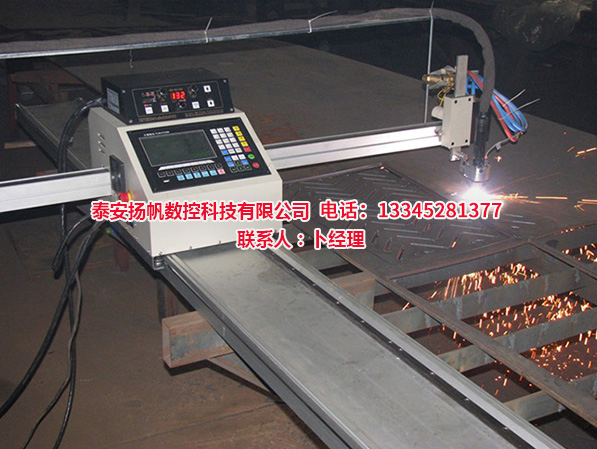

本文的精彩內容由焊接設備提供,更多的內容請點擊我們的網站:http://www.opedost.com或者來電咨詢

The exciting content of this article is provided by welding equipment. For more information, please click on our website: http://www.opedost.com Or call for consultation。

上一篇:使用焊接設備該怎么選

下一篇:山東自動焊接設備:揚帆數控提示您,選購設備要仔細