自動焊接設備會對電機繞組有不良影響嗎?

來源:http://www.opedost.com/ 發布時間:2023-03-09 瀏覽次數:0

自動焊接設備會對電機繞組有不良影響嗎?焊接是電機產品繞組加工中非常重要的工序。無論是模壓繞組還是散嵌繞組,無論是繞組與引線的連接還是繞組中主線之間的連接,焊接都是非常重要的環節。在對故障電機進行分析和處理的過程中,可以發現由于焊接質量差而導致的電氣故障并不少。

Will automatic welding equipment have adverse effects on motor winding? Welding is a very important process in the winding processing of motor products. Whether it is molded winding or loose embedded winding, whether it is the connection between winding and lead wire or the connection between main wires in winding, welding is a very important link. During the analysis and treatment of the faulty motor, it can be found that there are many electrical faults caused by poor welding quality.

不同的電機廠家對這一環節的加工工藝不同,但加工原理大致相同,即先清洗電磁線本身的絕緣層,無論是漆包線還是包線,這一環節都比較麻煩,尤其是多匝并聯繞組的情況下,電磁絕緣的清洗比本身的清洗更加困難,有的廠家用刮刀,有的用化學方法,但無論哪種情況,效率都很低,更嚴重的是,當電磁線絕緣層處理不徹底時,焊接效果差,在半成品檢驗和電機出廠試驗時可能不會暴露問題,電機在運行中容易出現故障。

Different motor manufacturers have different processing processes for this link, but the processing principle is roughly the same. That is, first clean the insulation layer of the electromagnetic wire itself, whether it is enamelled wire or wrapped wire. This link is more troublesome, especially in the case of multi-turn parallel winding, the cleaning of the electromagnetic insulation is more difficult than its own cleaning. Some manufacturers use scrapers, some use chemical methods, but in either case, the efficiency is very low, and more serious, When the insulation layer of the electromagnetic wire is not completely treated, the welding effect is poor, and the problem may not be exposed during the semi-finished product inspection and the motor delivery test, and the motor is prone to failure during operation.

針對這個問題,山東自動焊接設備應運而生。該設備在焊接過程中,通過高溫加熱清洗電磁線上的絕緣層,通過熱熔將焊接對象熔為一體,是一種非常高能效可靠的焊接方法。大多數自動焊接設備采用逆變電源技術和微電子控制技術,具有控制精確、工藝適應性廣、、高能效、穩定、操作簡單等優點。

To solve this problem, Shandong automatic welding equipment came into being. During the welding process, the equipment cleans the insulation layer of the electromagnetic wire through high temperature heating, and fuses the welding object into one through hot melting, which is a very high energy efficiency and reliable welding method. Most automatic welding equipment adopts inverter power technology and microelectronic control technology, which has the advantages of accurate control, wide process adaptability, energy saving, high energy efficiency, stability, and simple operation.

對于大型銅排轉子電機繞組,中頻焊接的應用效果較好,對于大部分零散的嵌入式繞組和成型繞組,自動化焊接設備應用廣泛,這也是提高電機生產加工效率和質量的基礎。

For large copper rotor motor windings, the application effect of medium frequency welding is good. For most scattered embedded windings and formed windings, automatic welding equipment is widely used, which is also the basis for improving the efficiency and quality of motor production and processing.

此外在一些經常移動的焊接設備中,由于接地(零)線經常被忽視,一些操作人員可能會同時接觸有零和無零的焊接設備,嚴重時會造成燒傷、觸電等嚴重事故。電擊傷主要是對人體外部的局部傷害,包括電弧燒傷等。

In addition, in some frequently moving welding equipment, because the grounding (zero) line is often ignored, some operators may contact the welding equipment with zero and without zero at the same time, which may cause serious accidents such as burns and electric shock. Electric injury mainly refers to local injury to the outside of human body, including electric arc burn.

為了保證人身和焊接設備的性能,預計使用多年。除了保證焊接設備(如焊機外殼等)可靠接地外,建議每三個月進行一次維護。并且用干燥的壓縮空氣吹動電源內部的飛濺物和灰塵。只有這樣,焊接設備才能長期可靠、地運行。

In order to ensure personal safety and the performance of welding equipment, it is expected to be used for many years. In addition to ensuring the reliable grounding of welding equipment (such as welding machine shell, etc.), it is recommended to carry out maintenance every three months. And use dry compressed air to blow the splashes and dust inside the power supply. Only in this way can the welding equipment operate reliably and safely for a long time.

以上就是問題的解答內容了,您可以作為參考使用,當然為了更好的進行使用,建議您在平常的操作中多多進行了解,并做好預防措施,更多事項就來我們網站http://www.opedost.com咨詢!

The above is the answer to the question. You can use it as a reference. Of course, in order to use it better, we suggest you learn more about it in normal operation and take preventive measures. More matters will come to our website http://www.opedost.com consulting service

上一篇:操作焊接專機時應注意的一些事項

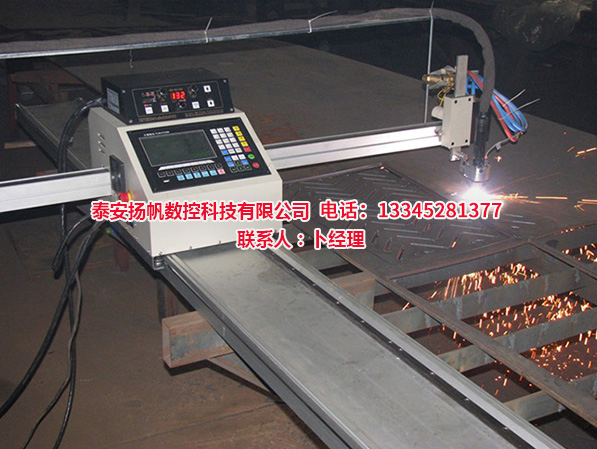

下一篇:數控切割機日常使用的一些技巧